Proven performance, every single time.

In-house facilities

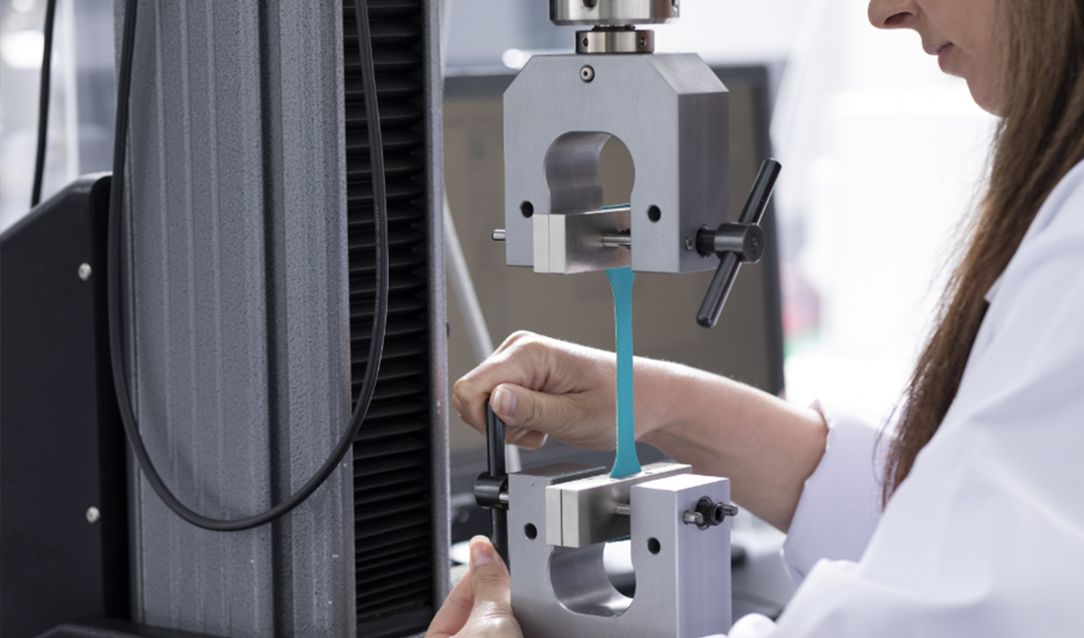

Every batch of Muirhead leather is tested in-house at our state-of-the-art material testing laboratory and R&D facility. We test to the individual customer’s specification, and supply a laboratory report ensuring that our product conforms exactly to their specification.

Pre-stressed testing

Most textiles testing carried out by other manufacturers is applied to new materials, which does not reflect real-world use. At Muirhead, we ‘pre-stress’ test samples by exposing them to extreme ranges of temperature and humidity to simulate years of real-world service and gather more realistic, useful data. Only then do we begin testing our leather’s performance.

Performance benchmarking

Continuous testing ensures that Muirhead leather delivers on its performance promises. We can benchmark against competitors and verify that leather aligns with specific needs. And we use internationally recognised methods in the aviation, passenger transport and furnishing industries.

Certifications, accreditations and approvals

Our Laboratory can provide testing for strength, stretch, flexibility, rub and abrasion characteristics as well as fastness and soil resistance. Our Laboratory is UKAS accredited per ISO 17025 to carry out FAA 25.853 appendix F pt.1 Vertical Flame testing and ABD0031 issue F Smoke Density & ABD0031 issue F para 7.4 Toxicity testing. View and download our UKAS Schedule of Accreditation.

We also hold certifications to AS/EN 9100, ISO 9001, IATF 16949, ISO 14001, ISO 45001, ISO 50001, BS EN 1021-1 and BS EN 1021-2. In addition, we have Marine Equipment Directive (MED) Approval and Vehicle Certification Authority (VCA) Type Approvals.

Our certificates are available to download:

EN 9100 and ISO 9001

ISO 14001

ISO 50001

ISO/IEC 17025 Certificate

ISO/IEC 17025 Testing Schedule

IATF 16949

OHS 45001

MED Type Approval

MED CofC

VEC Approval