- Leather specialist Muirhead opens multi-million-pound Super Tannery, slashing energy use by 82% and water use by 42% thanks to innovative hide processing technology.

- State-of-the-art facility builds on Muirhead’s parent company, Scottish Leather Group’s 20-year commitment to sustainable innovation and will boost production of the world’s lowest-carbon, high-performance leather.

- Group’s newly released ESG report reveals 100% supply chain traceability and 90% reduction in the carbon intensity of its leather over two decades.

Paisley, Scotland – Muirhead – a trusted supplier of lowest-carbon high performance leather to the aviation, rail, bus and coach industries – has today announced the opening of its £14 million, hyper-efficient Super Tannery.

The landmark project, which has taken seven years to deliver, will build on Muirhead’s world-leading sustainability standards and further enhance the production of the world’s lowest-carbon leather for aviation and passenger transport.

Setting new standards for leather manufacture, the new facility is the result of the latest round of multi-million-pound investments by Scottish Leather Group in its world-class facilities and forms part of the group’s 20-year strategy and commitment to continuous improvements in sustainability.

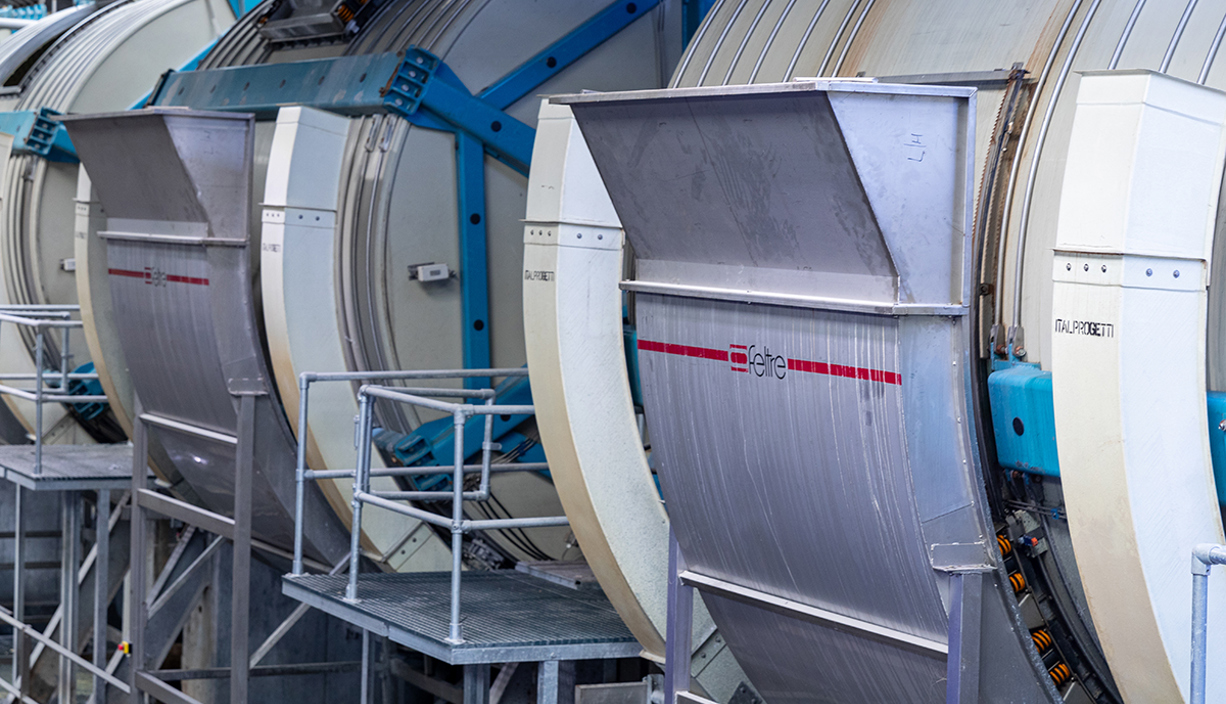

Tanning is a crucial part of the leather production process, whereby the raw hides are treated in drums filled with water and tanning agents to transform them into Muirhead’s durable, high-performance leather material.

The 14 new ‘super’ drums replace 30 conventional hide drums, enabling Muirhead to process greater batches while unlocking significant improvements in environmental performance. The tannery’s innovative hide processing technology brings about a further step change in energy and water use, with a reduction of 82% in energy use and 42% in water use compared to the group’s previous equipment.

Nicholas Muirhead, Chief Executive Officer, Scottish Leather Group, said:

“Since 2003, we have continuously invested in strategic initiatives designed to optimise and improve productivity, quality and sustainability.

The new Super Tannery is the latest significant milestone on that journey, a state-of-the-art facility that builds on the considerable savings we have already made in reduced energy and water use, improving our efficiency, and futureproofing our production. This will provide our customers with further evidence of our position as the leader in the supply of the world's lowest carbon leather.”

Dr Warren Bowden, Head of Innovation & Sustainability, Scottish Leather Group said:

“Over the last 20 years, we have pioneered and patented circular manufacturing processes that minimise waste to landfill and radically reduce our carbon footprint, with initiatives such as our Thermal Energy Plant and Ultrafiltration plant.

“The Super Tannery builds on these sector-leading actions, providing a step change in productivity and environmental savings. Our sustainability journey is continuous, and this new facility will play a vital role in enabling us to achieve zero impact leather manufacturing. We are committed to net-zero for our own operations (Scope 1 and 2) by 2025 – twenty years ahead of Scotland’s overarching net-zero ambitions – and delivering zero waste to landfill by the same year, further fortifying our sustainability pledges.”

Despite the dramatic increase in efficiency, Scottish Leather Group will retain the same number of technicians on site, as skilled workers remain crucial to ensuring the company’s sector-leading quality standards. In addition, and as part of the group’s commitment to complete circularity, the outgoing wooden drums from the tannery have also been stripped down and repurposed.

The new Super Tannery, which is now fully operational, will enhance Muirhead’s sector-leading Life Cycle Analysis, which provides operators with an independently verified, quantifiable assessment of the leather’s overall environmental impact. According to the ISO-accredited analysis, Muirhead’s 8kg CO2e/m2 LCA is currently the lowest in the world published for genuine leather.

To further underscore its commitment to sustainability, Scottish Leather Group’s newly released 2023 ESG (Environmental, Social, and Governance) report details its commitments and progress around environmental performance, Health & Safety, compliance, and traceability. Among the highlights are a 90% reduction in the carbon intensity of its leather over the last 20 years, as well as 100% supply chain traceability.

As highlighted in the ESG report, the group’s operations were recently re-certified as ‘Gold’ standard by the Leather Working Group (LWG), while its ethical working practices were endorsed by the leading international platform, the Supplier Ethical Data Exchange (SEDEX) for which assures ethical trading and compliance with international labour standards, adherence to the Ethical Trading Initiative (ETI) base code and compliance with International Labour Organisation (ILO) standards.

Muirhead’s high performance leather products are trusted by more than 160 airlines, airframe, and seating manufacturers globally – as well as most European bus, coach, and rail operators.